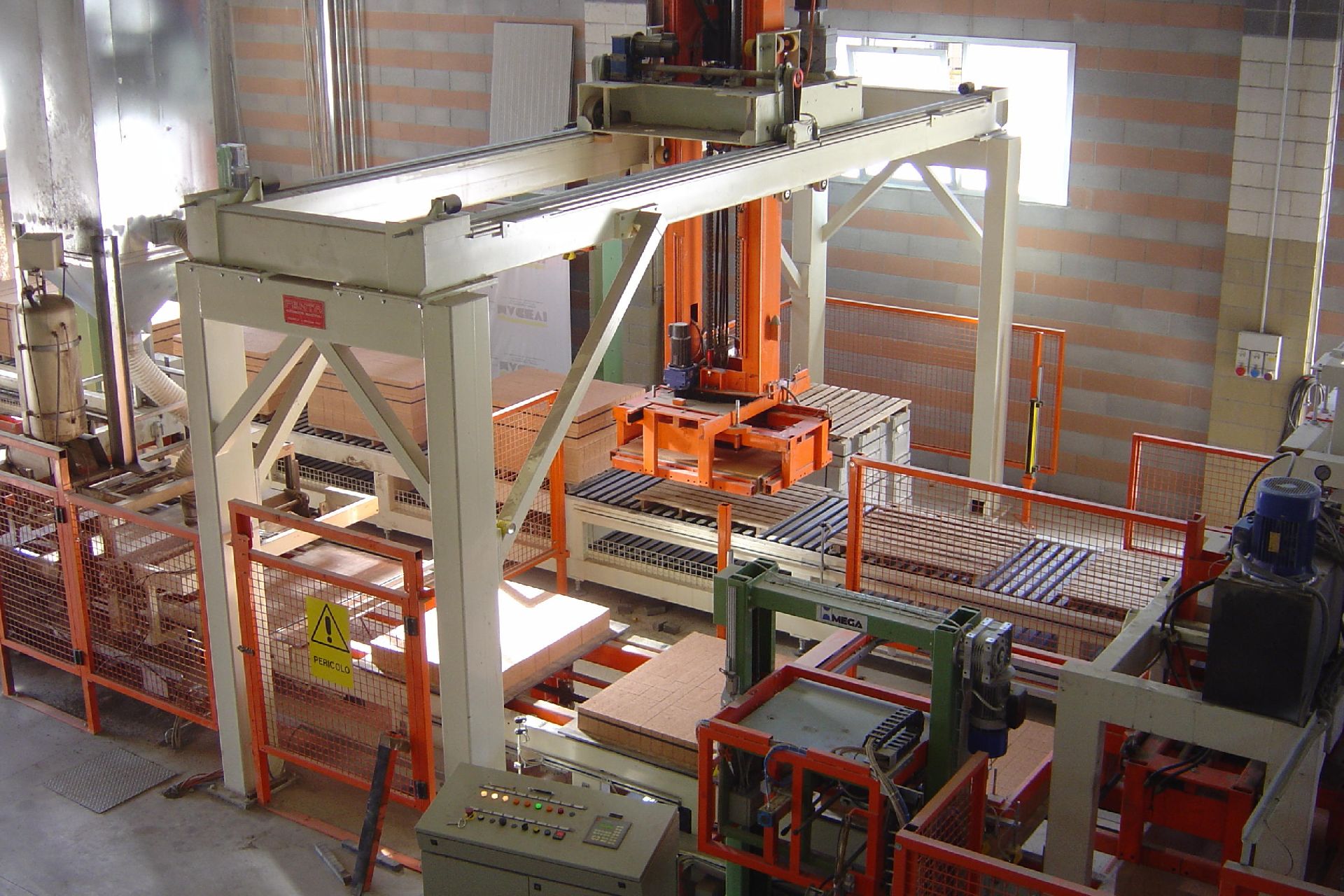

HANDLING SYSTEM FOR THE PRODUCTION OF CONCRETE PAVERS, BLOCKS, KERBS AND PIPES

For nearly 30 years Penta has been producing customised plants for its clients, developing the flexibility of the proposed systems and adapting them to realize highly innovative plants that could satisfy any production need and request.Production plant for concrete products

One of the results of the constant research of our technical dept. is the development of fully-automated handling plant that can be conceived for concrete pavers, blocks, kerbs and pipes and almost every other concrete product.

We are aware that handling systems are fundamental to produce high quality products and so we will study together with the customer, the best solution to achieve the most economical ad effective production process.

This system can be integrated with every block machine and both the grippers and the transfer car, equipped with Brushless motors that grant extremely precise variable speed movements, will be designed to keep up with the production cycle, while the block machine will be integrated with the entire system.

Beside this Penta can offer a wide range of stacking grippers that can handle not only any type of concrete pavers, blocks, kerbs and pipes, but also very special products like roof tiles and concrete barbecues. Penta indeed, supplied several handling plants for producing barbeques to the European leader in the market.

Handling so many different types of products, high pliability and adaptability of the proposed solution is a must. This capacity is easily verifiable by the multiple possibilities of the stacking operations: void packs or pallet less packs; first and second quality packs; stacking of different concrete tiles in a unique pallet and many more.

Moreover the production plants can be equipped with grippers for feeding any other secondary treatment process like aging, washing, shot-blasting, splitting, pitching, etc.

According to some special and particular production needs, the grippers can be replaced by extremely reliable and precise robots as they offer such a wide flexibility that it would be hard to achieve with grippers.

The handling systems proposed by Penta can also be completed with packaging lines that can be integrated with pallet dispensers and other packaging machines (like strapping and hooding machines) or systems to protect the surfaces of your pavers, blocks, slabs or pipes.

This handling system and all the equipments that can be combined with it can also be adapted to use flat beds to store the concrete pavers, blocks, kerbs and pipes. This particular type of production boards, equipped with feet, can be stacked one above the other so it is not necessary to have curing chambers to dry the products but it is possible to create storage by superimposing the flat beds.

Penta is glad to offer its customer turn-key plants and we will look after all the steps from the design up to the commissioning.